| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : FOTMA

Model Number : Customized

Certification : ISO9001:2008

Place of Origin : China

MOQ : 10pcs

Price : Negotiable

Payment Terms : T/T, Western Union, PayPal, L/C

Supply Ability : 100000pcs/month

Delivery Time : 20-25 days

Packaging Details : Paper cartons or Plywood boxes

Material : Cemented Tungsten Carbide

Material Grade : YG15, YG8, YG6 etc.

Surface : Machined, coated

Application : Woodworking Chop Saw Blades

OEM : Acceptable

Hardness : ≥90 HRA

Cemented Tungsten Carbide Cutting Tools Carbide Chop Saw Blades For Wood Working

How to Make the Cemented Carbide Chop Saw Blades for Cutting Tools?

A). Tungsten carbide tipped chop saw blades: The saw blades' teeth are tipped (via welding) with

small pieces of sharp tungsten carbide block. Tungsten carbide tipped saw blades are widely

used to cut wood, plywood, laminated board, plastic, grass, aluminum and some other metals.

B). Tungsten carbide chop saw blades: The whole saw blade is made of tungsten carbide. Comparing

with HSS saw blades, solid carbide saw blades have higher hardness under high temperatures,

and are more durable, but they also have a lower toughness.

Applications of Carbide Chop Saw Blades:

For slotting in the spectacles frame's industry;

For computer hard disk head industry;

For cutting/scoring the pcb board;

For artificial crystal slotting/cutting;

For jewellery (gold, silver, copper)accessory industry;

For metal (alloy) precise cutting/slotting;

Advantages:

1) Long life with super resistance to heat, wear and abrasion

2) Use coarse grit for faster cutting of thick materials or metals;

3) Use medium grit for thin materials and fine finishes

Material Grades for Cemented Tungsten Carbide Chop Saw Blades:

| Grade | ISO | Density g/cm3 | Hardness HRA(hv) | T.R.S | Performances & Applications Recommended |

| YG6 | K20 | 14.9 | 89.5 | 2150 | Good Wear resistance, used for hard wood,processing original wood, aluminum section bar,brass rod and cast iron. |

| YG8 | K30 | 14.6 | 89 | 2320 | Suitable for the roughening of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YG15 | K40 | 14.1 | 86.5 | 2400 | Qualified for hard rock drilling, steel bars with high compression ratios, pipe drawing, punching tools, core cabinet of powder metallurgy automatic molders etc. |

| YS2T | K30 M30 | 14.45 | 92.5 | 2800 | Fine carbide,high wear resistance,high bending strength,high resistance to bonding, high thermal strength.Machining of refractory alloys, stainless steel and high manganese steel etc.Mainly used for disc cutter and other tools. |

| YL10.2 | K25-K35 | 14.5 | 92.5 | 3400 | Wear resistance and strength comparatively higher,suitable for processing cast iron, non-ferrous metal and non-metalloid materials. |

| YNi8 | / | 14.6 | 88.5 | 1710 | This grade with 8% nickel binder, it has good wear resistance & corrosion resistance performance, especially used for high pressure environmental, also good for cutting the titanium alloy. |

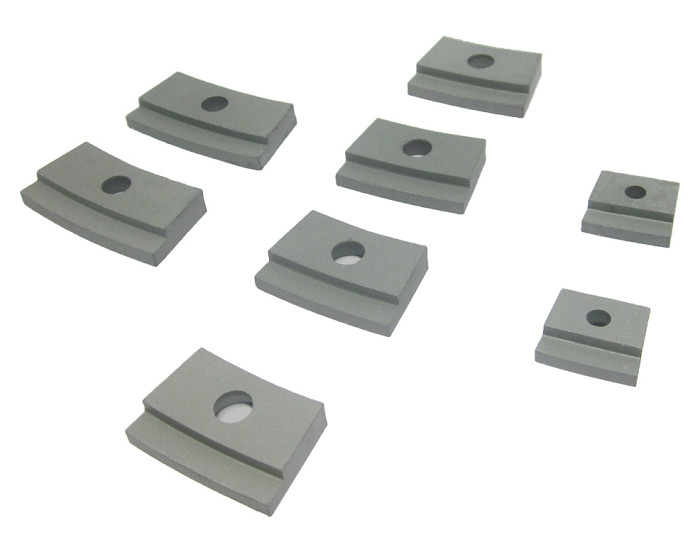

Product Show:

|

|

Cemented YG15 Tungsten Carbide Cutting Tips For Wood Working Images |